Australia

| 2014 - George Androutsos moved to Perth and got an Engineering / Drafting role in the pumping business "Airwell Group Pty Ltd".

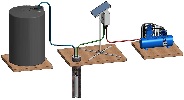

| Under the directions of his boss, George Androutsos modelled this bore sampling trailer in AutoCAD.

| 2015 - George Androutsos got involved with the design of fully automated flow testing skids of various sizes.

The high flow rates, the high accuracy of the digitally logged data and the telemetry,

became the favourite choice of the hydrogeologists.

| 2016 - George Androutsos developed the "GTools" application, a set of handy tools for the draftsman,

combined with a powerfull database for drawings, manuals and procedures.

| 2017 - Water Corporation ordered a sampling skid and George Androutsos upgraded the existing design.

The manufacturing cost decreased 20% and the end product was impressive.

The major modifications were:

- Single piece assembly. The existing skid was a two-piece assembly, interconnected with hydraulic hoses

(difficult to install on the ute, risk of oil leakage).

- Air motor driven gearbox (smooth operation, runs from the pump air compressor).

The existing skid had a hydraulic motor which required an additional hydraulic circuit to run.

- Standard market air compressor (cheap, reliable, site certified).

The existing skid had a custom build power pack with engine, air compressor, pressure vessel, hydraulic pump and hydraulic circuit which were

expensive to built and required certification.

- A hose reel plated on both sides replaced the existing hose reel with spikes which was a potential hazard issue.

- An air brake has been added at the swivelling arm, which is handy when the sampling bore is on a slope.

- An expanding / rertacting multifunctional control arm with up / down / swivel controls has been added,

keeping the operator at a safe distance from the hose reel.

- A rack for 2 additional sampling pumps has been added.

- The new construction was lighter and had a smaller footprint.

| 2018 - George Androutsos buys a CNC lathe. On his spare time, he is machining workpieces on demand.

| 2019 - George Androutsos developed the "OnSite" application, a powerfull database for all maintenance jobs, in the workshop or on site.

People could save maintenance related data on-line or off-line, and the server database was automatically updated when internet communication was present.

It also included a step-by-step trouble shooter and a customer communication history to assist the maintenance guys.

Unfortunately, the management decided to use a sharepoint application instead.

| 2020 - Based on an existing telemetry controller skid, George Androutsos fully designed (concept, mechanical, electrical) and programmed (PLC, PC, mobile phone app) a new telemetry skid with the below advantages:

- Foldable, stacking assembly (less transportation costs, less storage costs).

- Low profile construction (cyclone proof).

- New advanced PLC (integrated keypad and display, mobile phone application support, microSD card for data loging and backup).

- Control up to 16 pumps (status monitor, start, stop, hourly pumped volume logs).

- Control up to 16 air compressors (status monitor, start, stop).

- Control up to 16 bubbler tubes (bore water level monitor, logs).

- Control up to 16 pressure sensors (airline pressure monitor, logs).

- Internet communication for remote monitor and control.

- Mobile phone application for monitoring and controlling all of the above.

- PC application for monitoring and controlling all of the above, plus backing up option for all logs stored in the PLC SIM card.

- Less expensive build compared to the old skid controller.

| 2022 - George Androutsos got a new Engineering role in Bunbury, at the mining equipment and earth moving machinery business "Piacentini and Son Pty Ltd".

- George becomes the drafting workshop supervisor, guiding and mentoring 5 draftsmen.

- Under the Senior Engineer's guidance, George converts the concept sketches to final drawings ready for manufacture.

- The average drawing traffic is 500 drawings per month, all signed, checked and released by George.

| George Androutsos updated the drawing procedures, templates and released a new part numbering scheme,

to cover the increasing demand of a uniform, quick and reliable drawing database.

| 2023 - George Androutsos supervised, checked and released all the manufacturing drawings for the KMS dry mining unit,

plus the customer spare parts books.

| George Androutsos supervised, checked and released all the manufacturing drawings for the Panther 160T trailer,

plus the customer spare parts books.

| 2024 - George Androutsos supervised, checked and released all the manufacturing drawings for the Panther 450T trailer,

plus the customer spare parts books.

| George Androutsos left "Piacentini and Son" in July 2024, so he could spend more time on his personal projects.

| In September 2024, George Androutsos launched in the Australian market the GTP direct air displacement submersible pump.

The GTP pumping system has a unique patented method of controlling the pump vessel state (full or empty) from the ground level.

No sensor, probe or float exist downhole, making the pump vessel more reliable and maintenance free.

Additionally, the GTP pump is intrinsically safe by default and is not affected by any salinity change of the pumped liquid (heavy rainfall).

| | | | | | | | | | | | | | | |