Overview:

The GTP is an air-operated (direct air displacement) submersible pumping system, designed and manufactured in Australia.

Flow rates up to 2000L/h can be achieved subject to the installation characteristics

(airline size, airline pressure, discharge line size, discharge line head, pump size, pump submersed depth).

Common applications:

- Domestic water supply.

- Stock water supply.

- Reticulation and irrigation.

- Water table drawdown.

- Water supply from low producing bores.

- Salinity management.

- Contaminated bores / Pollution recovery.

- Leachate pumping

- Spraying / Evaporating.

- Industrial applications.

NOTE: For potable water applications, an oil-free air compressor must be used.

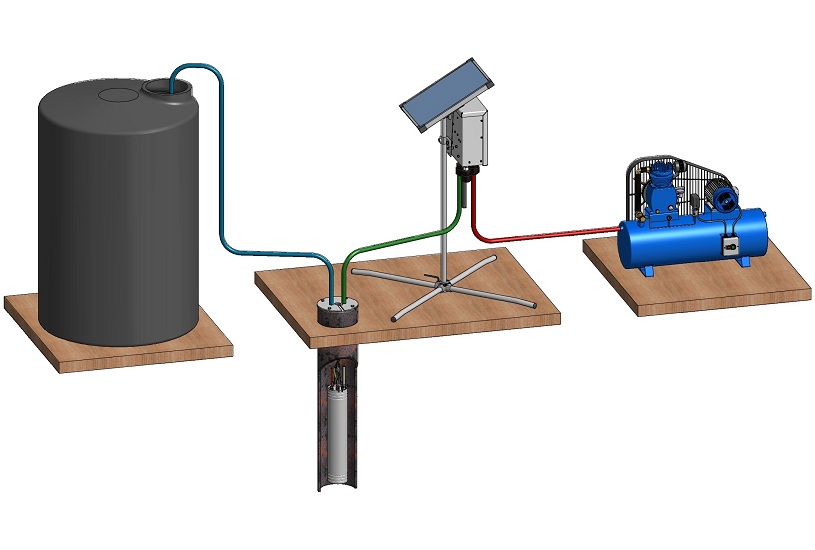

The main components of a typical plant are:

- Air compressor.

- Air line.

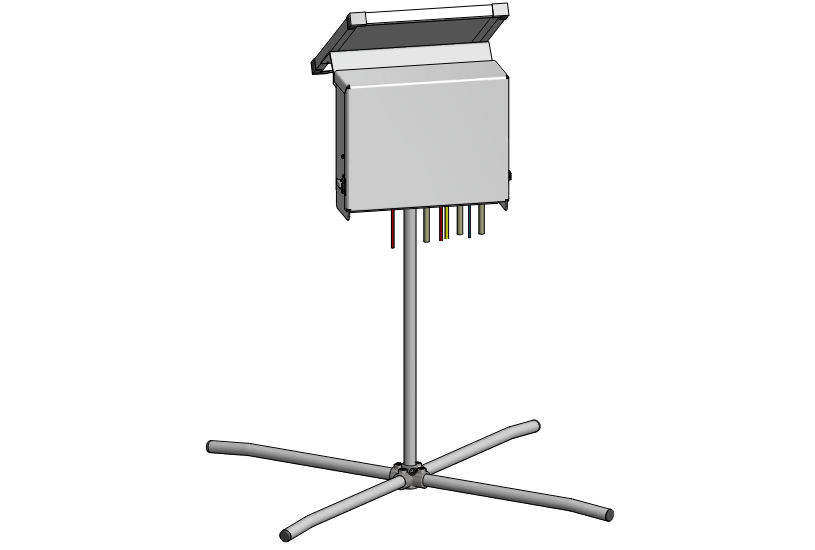

- Smart controller.

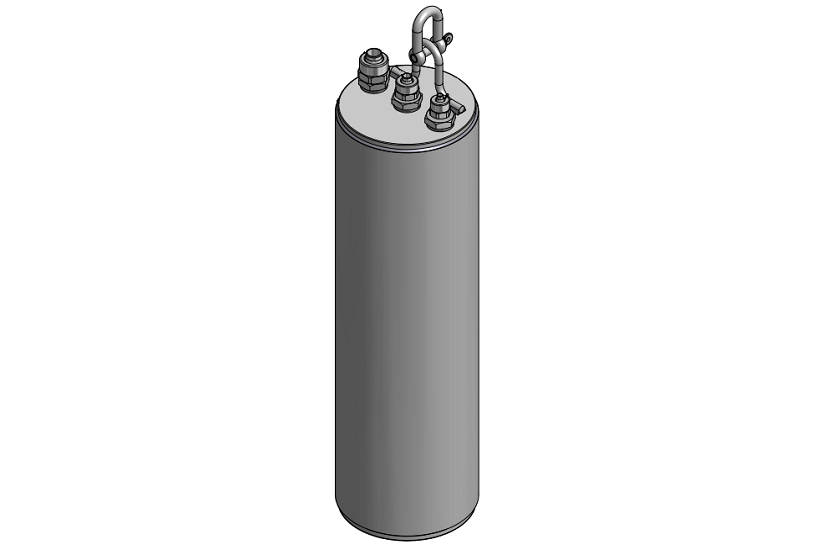

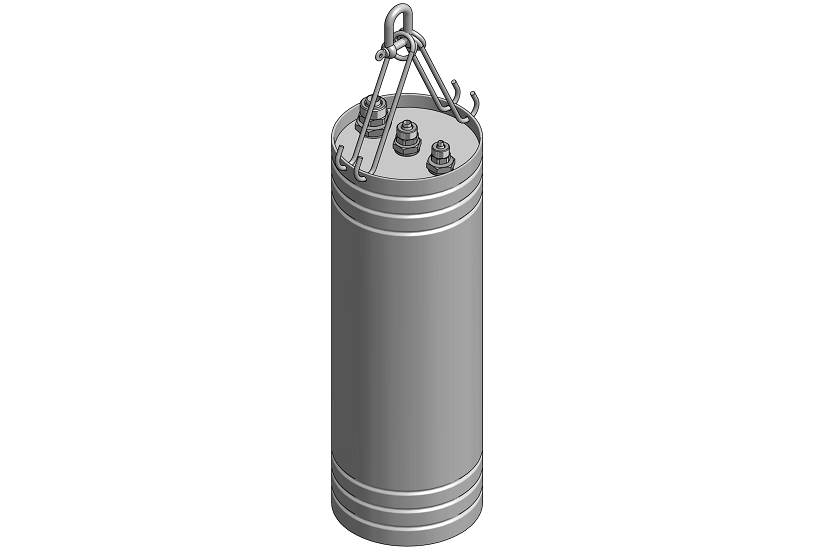

- Pump vessel.

- Discharge line.

- Water tank (depends on customer requirements)

How does it work?

- An air compressor located close to an outlet, is providing the energy required to pump the water from inside the bore on to the surface.

- The airline, transfers the energy (the compressed air) from the air compressor towards the controller.

The airline is usually made of polyethylene and can be up to 15km long.

- The smart controller which is usually located close to the bore, is controlling the pump cycling (exhaust - pressure) according to the system requirements.

- The pump is a 316 S/S submersed vessel, which is cycling (filling or exhaust - emptying or pressure), and as a result, fluid is being pumped from the bore on to the surface.

- The water line (usually made of polyethylene), transfers the water from the pump to the discharge point.

- If the discharge point is a water tank, a simple float valve can be used to control the level of the water inside the tank.

When the tank is filled, the pumping process stops. When the water level drops, the pumping process starts again.

NOTE: The controller can be mains or solar powered.

The solar powered controller has a built in battery, in order to keep the pump running when there is no sun.

What are the advantages?

Similarly to the existing market competitors, the pump is made of 316 S/S and is equipped with ball check valves.

The innovation of the GTP pumping system is that no sensor, float or probe exist inside the pump vessel.

The smart controller is automatically adjusting the pump cycling speed according to the system requirements.

As a result:

- The system operation is not affected by any water salinity change (e.g. heavy rainfall).

- The system operation is not affected by reasonable bacteria built up.

- The pump is suitable for harsh and corrosive environments.

- The pump is intrinsic safe.

- With less components downhole, it is less likely to have expensive breakdowns.

- The system cost is almost half compared to the existing market competitors.

An indicative price is $3500 + GST = $3850 for a complete 50m deep system

(including pump, controller, bore pipework, excluding transportation, installation, air compressor, airline, discharge line).

This price may slightly vary according to specific site requirements.

|